Table of Contents

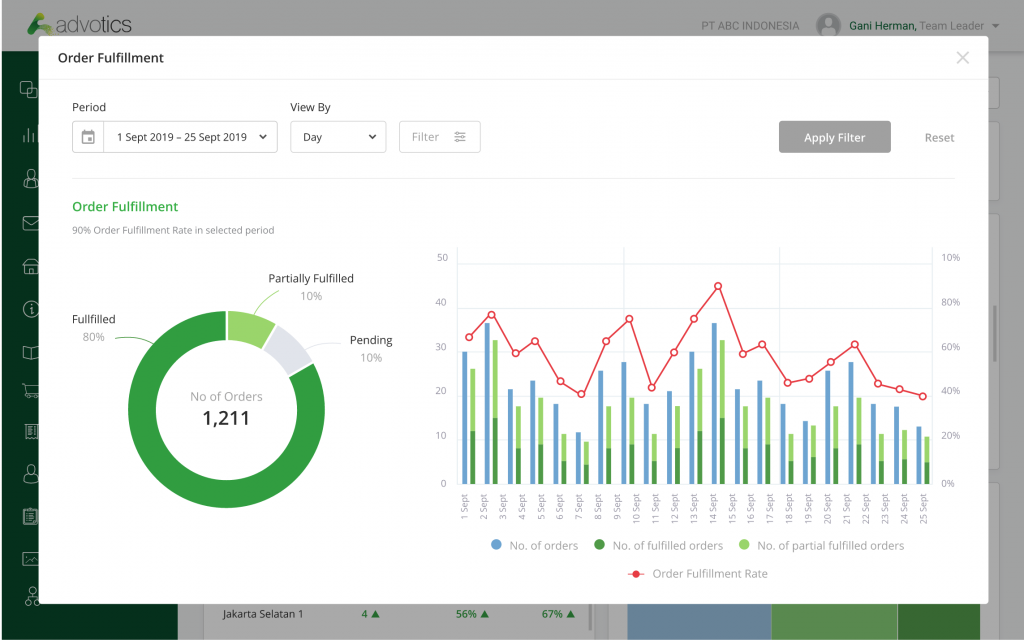

I. Order Fulfillment

Order fulfillment is a process that involves taking orders, processing, picking, packaging, and sending them to customers. Order fulfillment rate is the number of orders processed divided by the total number of orders received. The delivery of products to fulfill market demand is very important to grow and increase company profits. With this, management must always strive for the most optimal order fulfillment strategy.

II. B2B vs B2C Order Fulfillment

B2C orders are typically for e-commerce, in which they have less goods quantity in one order and are sent directly to the location of residence. Meanwhile, B2B orders are much larger in terms of quantity, but with less frequency. Oftentimes, your B2B clients will only order every few weeks or months, but the purchase quantities will be much larger.

III. Order Fulfillment Constraints

a. A delay of order receipt

Ideally, the head office immediately accepts the sales order request after the customer confirms it to the salesman, however, because the process is still executed manually, the order acceptance process sometimes becomes less transparent. For example, a sales order slip confirmation can be lost or duplicated so that orders received may be double or even not received at all. Not to mention the delay time required for salesmen to return to the office. Since B2B the process is more complex, the slightest obstacle can have a big impact on future client relationships.b. Inadequate inventory when demand is high

The company’s order management must be balanced, starting from forecasting market demand, to purchasing strategies. A client who is out of stock due to delays in restocking.may move to a competitor. Your relationship will be damaged and the likelihood that the client reorder will decrease. If your forecast is right, you can anticipate market demand more accurately. Then the stock of goods in your warehouse is always safe and thus can fulfill all client orders accurately.c. Complex logistics

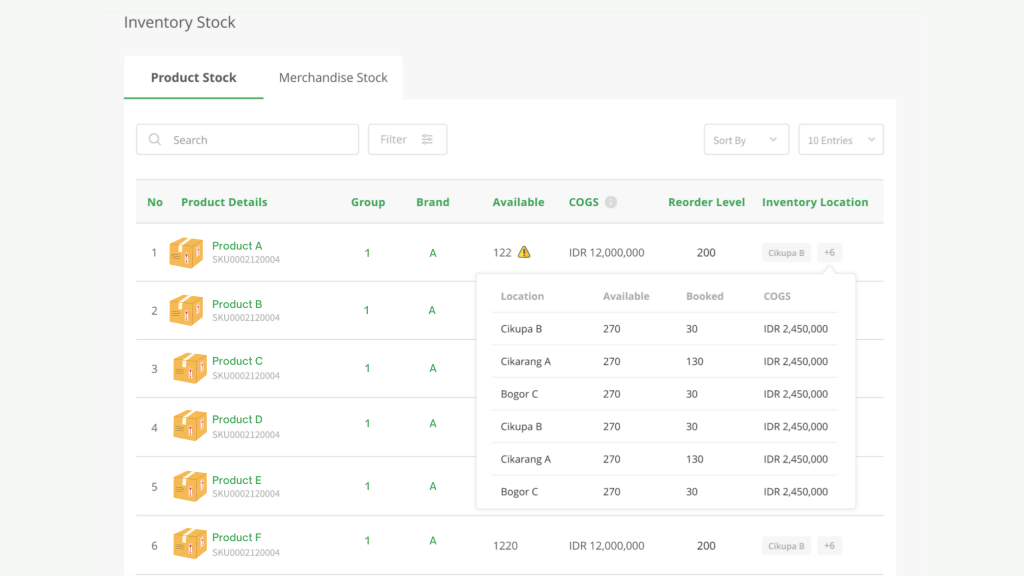

Since B2B order fulfillment involves shipping in larger quantities, the order value is much more expensive, and often requires more labor with complex equipment (pallets, loading and unloading trucks, etc.) and large companies sometimes operate multiple warehouses (multi-warehouse). These multi-warehouses are sometimes scattered in order to fulfill orders in each of their respective regions. However, with this multi-warehouse, there is also more complexity because the level of stock in one warehouse and another warehouse will be different. There needs to be real-time data transparency on all warehouses, so that the headquarter admin can allocate which warehouse will fill certain customer order. Manually counting stock, managing labor and orders can be complex and time-consuming. Any delays and mistakes on the ground can damage the company’s reputation, not to mention losses in terms of returns or refunds.IV. Strategy to Increase Order Fulfillment Rate

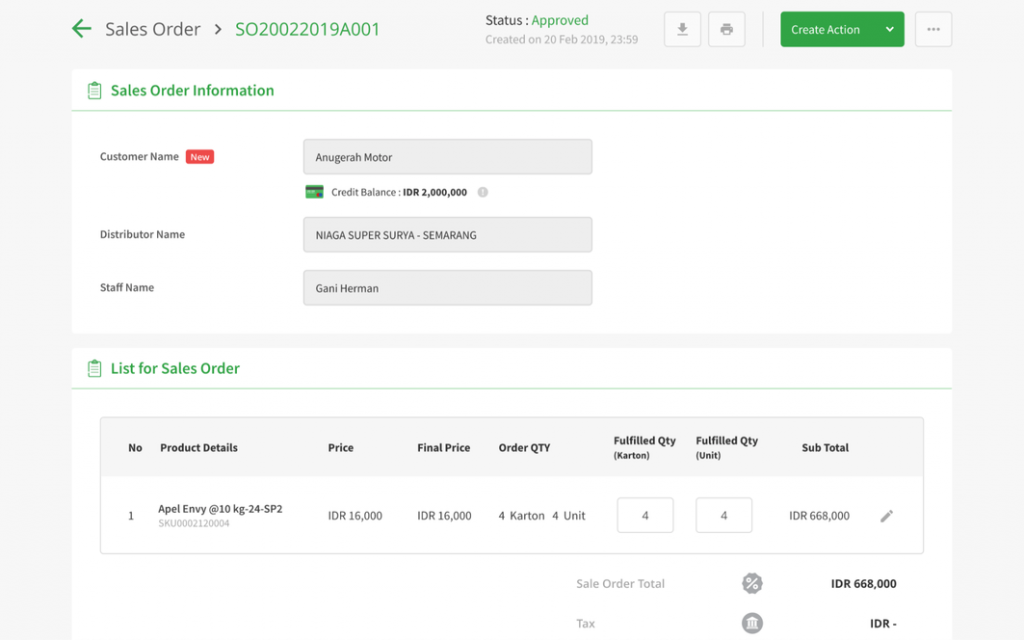

a. Streamline the ordering process

When an order is ordered by a client, the company’s salesman will use a system that integrates from submitting to receiving orders. The order quantity and remaining stock in the warehouse can be monitored, and the selected warehouse location can also be determined by the supervisor through the same system. With software, operators and management can update/revise information automatically, in addition to accessing stock levels and monitoring where the product is at from anywhere and anytime. So, when the goods leave the warehouse and are sent to the customer, the stock information in the database will always be accurate. Likewise, if there is a stock adjustment at the time of goods receipt or stock-taking, the operator can also add it to the system.

b. Real-time inventory management

After the product is produced or received from the principal, the warehouse must store it in an organized manner. First, the product needs to be received, counted, checked, labeled ID (barcode / QR codes), and input into warehouse management software or other ERP systems, then, then it’s time to store it in the warehouse.

An easily accessible warehouse storage system is very important for a smooth running of the order fulfillment process because a cluttered and messy warehouse will cause delays and inaccurate orders. Great inventory storage will maximize the speed and accuracy of order fulfillment.

One of the terms for inventory management is Hot SKU. This means that these goods are the best selling in the market, which is why they are placed the closest to the packing counter in a warehouse.

Software for distributors such as the Distribution Management System can determine which items are Hot SKUs and other variables that can improve your inventory management. DMS can provide comprehensive and real-time stock information to managers.

In addition, the stock level that is displayed real-time from this system is also a reference for the order fulfillment process, including choosing which goods will be fulfilled from which warehouse if the distributor operates several warehouses at once.

c. Speed up product delivery process

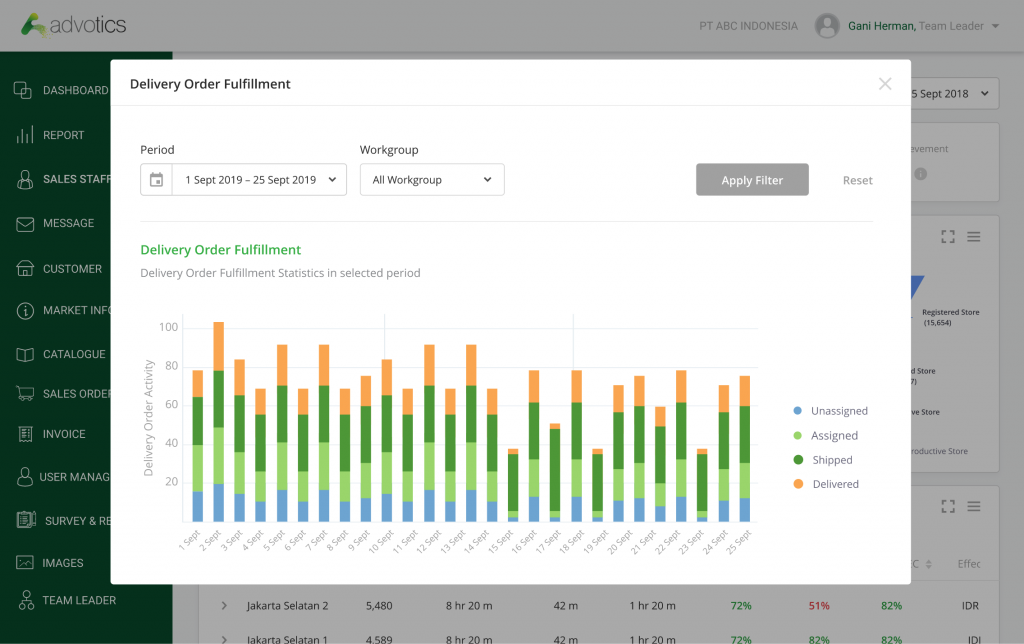

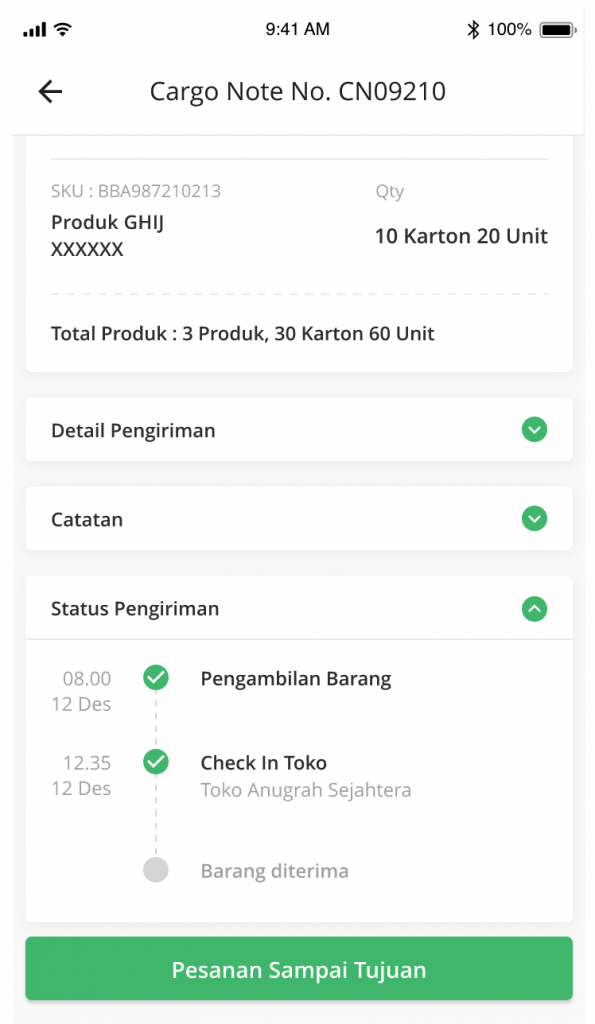

Couriers are responsible for updating the status from out of the warehouse to the point of delivery or shop locations. Distribution Management System application can assist managers in assigning couriers to deliver goods to clients and track their status.

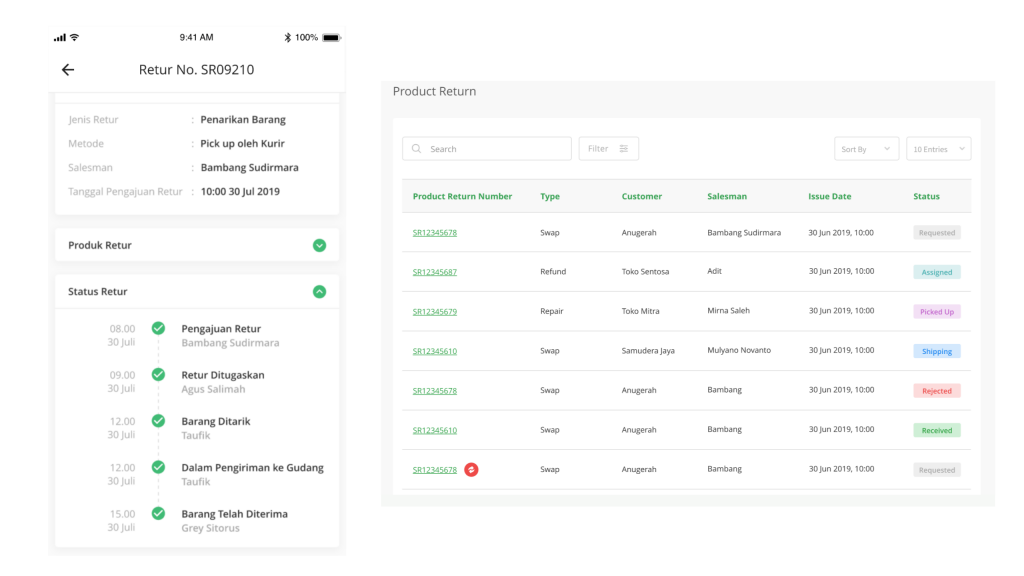

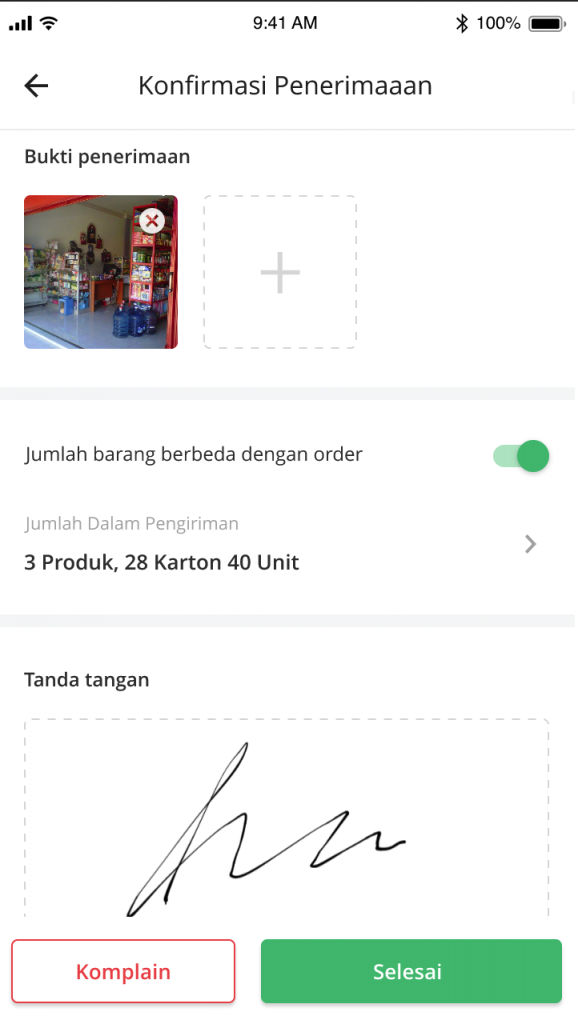

d.Product Return Processing

The buying and selling process does not stop when goods arrive in the hands of the client, sometimes goods must be returned because they are damaged, unsold, or expired. The product return process that starts from submitting product returns, withdrawing goods from customers to monitoring the status of the goods, are all tracked in the apps.