What is Track and Trace? What are the Benefits for Brands and Manufacturers?

Table of Contents

Can companies see the visibility of each product’s sales movement through their distribution layer clearly? Where and to whom is the product distributed before it reaches the consumer? Has the company used track and trace technology?

What is Track and Trace for?

In the conventional supply chain model, the visibility of the manufacturer or brand owner on product sales is limited to the distributor level only. However, companies that have an integrated supply chain system can increase their flexibility and speed in responding to external events.

External Events That Can Disturb Company Distribution and Brand Value

1. Products Spread in Improper Areas

In order to maintain market fairness and stability of the distribution network, many companies determine the distribution of sales areas per distributor or rayonzation. However, there are often cross-border transactions that can disrupt this stability. For example, when a distributor sells a product at a discount to a city that is another distributor’s area.

2. B2B Products Sold As B2C Products

Several companies sometimes sell products for B2B and B2C at the same time. However, those products are sometimes distinguished from their brand, size, or product design. If a B2B product is sold as a B2C product, it can hurt the company’s sales and branding in the market.

3. Exclusive Products For Sale in the Free Market

There are also products/brands that can only be sold through closed markets, for example through official agents, tiered marketing, etc. If a product is found to be sold on the free market, the retail price and revenue from the authorized agent may be disrupted.

4. Counterfeit products

Apart from problems in the sales channel, products on the market are also prone to counterfeiting. Products of premium value or that have an impact on human health such as medicines in particular will have a huge impact if the customer is proven to be fake. Therefore, if every product that leaves the factory cannot be traced, the product counterfeiting becomes difficult to stop.

Track and Trace Solution

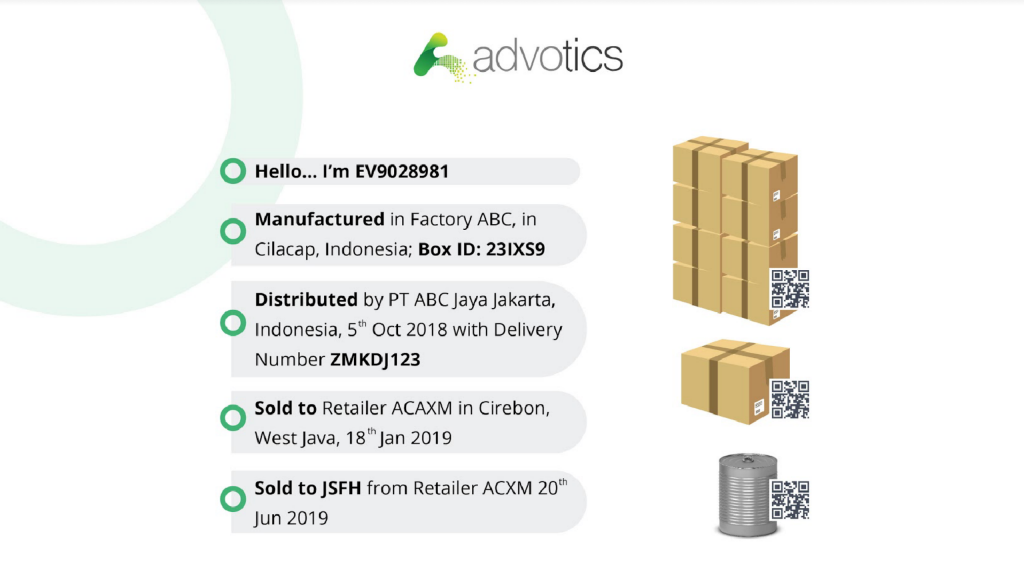

Technological advances in automation and the Internet of Things (IoT) have proven useful in increasing supply chain visibility. Track and trace is a system for recording product movements from production, warehouse storage, distribution to products sold in consumer’s hands. At each processing location (factories and distributors’ warehouses) the goods are identified and the information is sent to the system.

Product distribution history storage can be done for every smallest unit of product (bottles, boxes, cans, sacks, or other packages), not only per SKU. The information can be accessed by employees with proper access.

Track and Trace in Advotics Product Digitalization Management (PDM) Module

1. Provide a Unique Product Identity

Barcodes and QR codes are common methods that can be used to implement a unique identification for each product. Data variables can safely be used as a pointer to information such as production data, expiration time, etc., and can be accessed digitally for monitoring or analysis purposes.

2. Track and Log the Movement History of a Product at Various Points in the Supply Chain Layers

The barcode and QR code will be scanned at each point and every time the product passes through an activity. Advotics system can provide information on the location and status of products as they move along the supply chain layers in real-time. Management and supervisors can access the web portal complete with a map visualization to track the origin of products and to find out the last or current position of the product.

If a product is found in the wrong area, sold in the wrong channel, or even a counterfeit product is found, the operator can scan it and then trace the product’s movement history. For fake products, when the QR code is scanned, Advotics system can detect that the same QR code has been scanned by another party in a different area.

3. Analyze the Rich Data that the System Has Recorded to Create Strategies that Improve Distribution and Logistics Processes

The more activity and data recorded in the system, the better the insights produced.

If the company can see more granular information about the product distribution process, the company can easily overcome inefficiencies, respond to problems quickly, and make more tangible strategic changes. Product distribution visibility is the key to a smarter supply chain.