Table of Contents

What Is OEE? Why Is It Important?

What is Overall Equipment Effectiveness (OEE)?

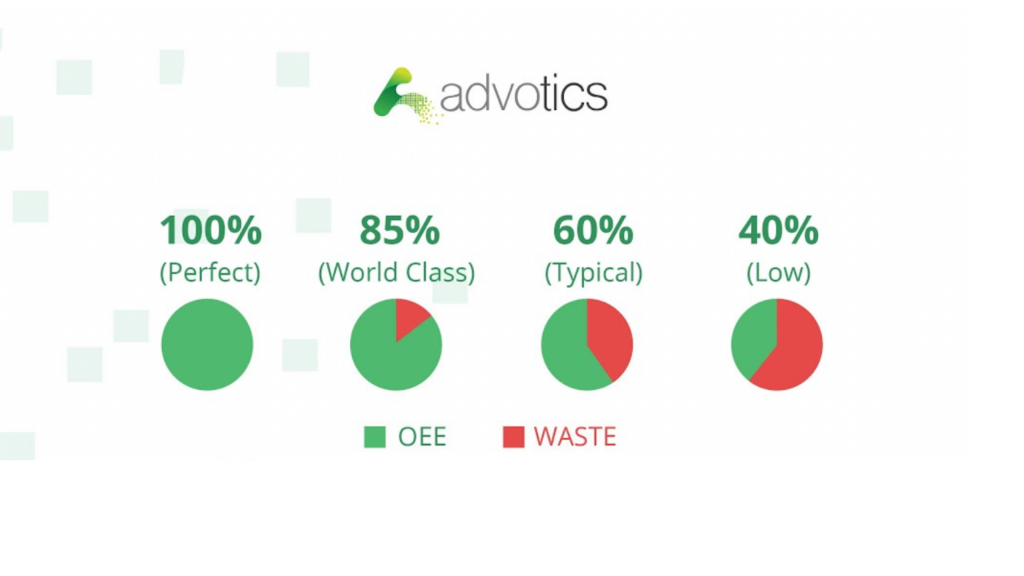

With increasing competition in the market, manufacturers must always ensure the most efficient operations to produce quality products. OEE is a standard for measuring manufacturing productivity. By measuring, companies will gain important insights to improve production processes and minimize waste of resources.

OEE is not only useful for measuring the company progress from time to time. It is also used to compare your company’s production performance against standards in similar industries.

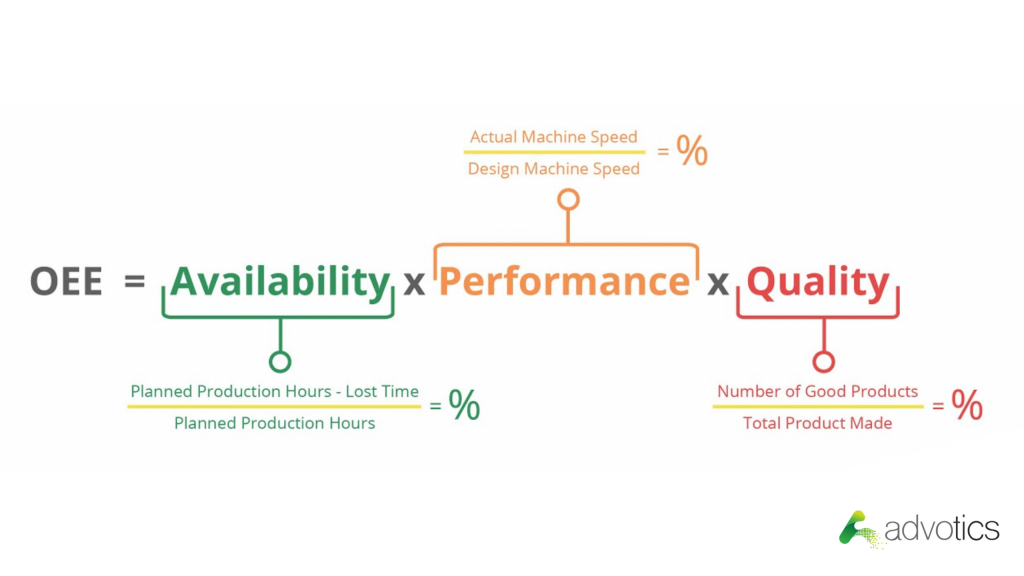

a. 3 Factors that cause low OEE values

- Availability -> total time when production stops, whether planned or not (shift change time, machine breakdown, lack of materials, etc.)

- Performance -> factors that cause production to run slower

- Quality -> products that do not pass QC

b. How to calculate

The higher the OEE value, the more efficient the manufacturing operation is. When the OEE value is at 100%, it means that the company only makes products with perfect quality (quality) as quickly as possible (performance), without planned and unplanned downtime (availability).

c. Data needed to measure OEE

- Number of Good Products = goods produced without defects, or the number of production minus defective products

- Actual machine speed = actual throughput or actual production per period

- Lost Time = total time the production process stops

If there is no ERP that can collect all data automatically, companies must rely on manual processes such as paper logs. However, due to the complexity of the manufacturing process, this process is too time-consuming and does not provide sufficient data to improve OEE.

Advotics dashboard shows OEE in real-time

Advotics Product Digitalization Management (PDM) dashboard displays important insights within the company, one of which is OEE in manufacturing plants. Overall Equipment Effectiveness value here is calculated automatically from the data Advotics processed and obtained from the field.

How Advotics Product Digitalization Management (PDM) Works

In the last process of the packaging line, the system will print QR codes on each product item (box, pallet, or other packaging). Then, before the product leaves the factory, it will be scanned for final QC. After that, because each product has been scanned into the system, the principal will be able to monitor the movement of the product until it is purchased by the end consumer.

Read more: The Next Manufacturing Revolution – Going for 4.0 With Advotics