Warehouse Business Intelligence for Principal and Distributor Logistics

Table of Contents

Why do Warehouses Need Business Intelligence?

Managing a warehouse seems like a simple concept: preparing enough stock to fill orders, but not so much that the warehouse is full. However, not all goods can be treated the same way. Some items move slowly, some require climate-controlled storage, etc. Hence, it is difficult for management to optimize warehouse layout and inventory storage all at the same time.

Warehouse operational challenges:

- Sudden increase and decrease in market demand

- The high cost of holding slow-moving stocks

- Stock items that require climate-controlled storage or take up significant space due to their large size

- Less than optimal use of warehouse capacity

- Other issues such as lost, damaged, or expired inventory

Early detection of inefficiencies in warehouse management with Warehouse Business Intelligence can help management make more informed decisions to increase sales, streamline operational processes, thus serve customers better, and find new opportunities.

What is Business Intelligence (BI)?

Business Intelligence is a business system used for data visualization, reports, and online data analysis. The analysis can be in the form of marketing strategy, operational efficiency, market pricing, profit, employee performance, sales forecasting, and other data.

The goal is to get comprehensive business insights in the form of data visualizations, dashboards, and reports; for c-level executives, managers, and data analysts. To do this well, companies need a centralized system that stores all data, so employees can find the data they need quickly, anywhere, and anytime.

Read more: Management Report System for Distributors and Principals

Advotics Warehouse Management System (WMS)

Advotics WMS is a software solution that easen companies to increase sales and order fulfillment rates by streamlining operational processes, managing and controlling inventory in several warehouses based on analysis data of incoming and outgoing stock. Such as:

- Stock Over Time = inventory level in warehouse

- Warehouse Utilization = warehouse capacity utilization rate

- Stock Position = list of all products and their status (overstock/understock/normal)

- Product Leaderboard = best selling products

- Stock Movement = total mutation of stock-in, stock-out, and current total stock

- Good Issue Cycle Time = average storage time of goods in warehouse

- Order Fill Rate

- Inventory Accuracy

The entire dashboard is updated in real-time without employees going back and forth to check the remaining stock.

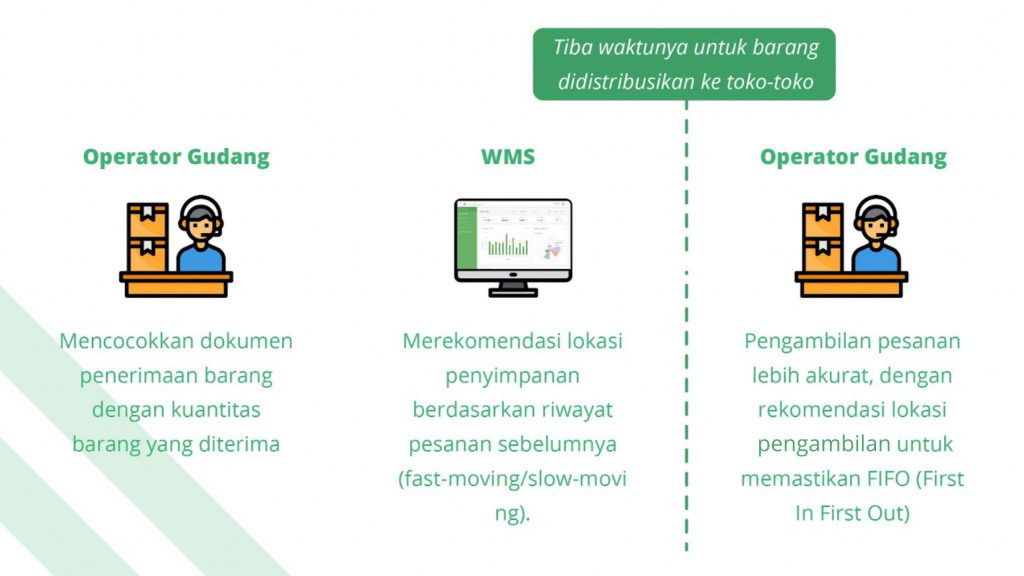

With Advotics WMS, warehouse operators can match goods receipt documents with the quantity of goods received. Once the goods arrive, WMS will recommend a storage location based on the history of previous orders (whether it’s fast-moving/slow-moving). When it comes time for goods to be distributed to stores, order picking is also accurate, with recommended pick-up locations to ensure FIFO (First In First Out).