Digitizing Supply Chain: Construction and Building Materials Industry

Table of Contents

The construction industry contributes approximately 10% of the national GDP. However, according to the Industry Digitization Index, it is the second-lowest industry in terms of digitization.

The construction and building materials industries constantly work on large-scale projects. The relationship between suppliers and contractors, project timeline, and budget monitoring are some of the important points that this industry needs to pay attention to.

With the large costs associated with it, more and more clients are pushing construction and building material companies to start transforming their workflow digitally.

Construction Industry and Building Materials Pain Points

Overtime and budget excess are some of the main results of inefficient supply chain processes. The following are some of the problems that are often faced by the construction and building materials industry:

- Lack of data transparency

- Slow information flow from different supply chain layers

- Unoptimized operating costs

4 Key Points on Why the Construction and Building Materials Industry Should Start Digitizing their Supply Chain

1. Transparency in product distribution with track and trace

Pain points:

With a manual system, companies find it difficult to know where their product is (which warehouse or at which project location), because there is no system integration with warehouse distributors and retailers. This data is important to know in order to obtain an accurate inventory level to anticipate market demand, optimize inventory costs, and determine the time to market.

Solution:

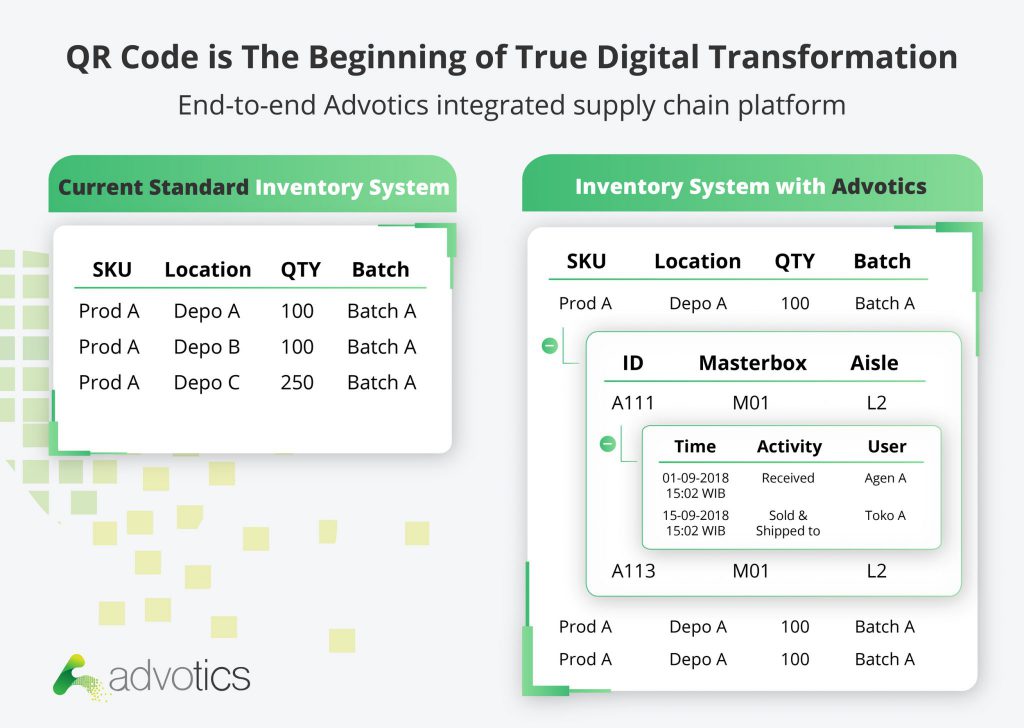

Application of Quick Response (QR) Codes technology on the packaging of each product as a unique digital identity. After the QR codes are scanned, the system will start tracking product movements (track and trace) starting from the Principal’s warehouse, trucks, distributor warehouses, salesmen couriers, until finally arriving at the store. QR codes can be placed directly on the product packaging or on the box/pallet.

Benefits:

The unique identity in each product helps the Principal in preventing counterfeiting of goods and cross-border transactions. In addition to real-time product monitoring, track and trace technology also optimizes production planning because it automatically tracks stock items in warehouses, sell-in, and sell-out on a real-time basis.

Read more: Revolutionary Warehouse Management System: A New Way to Identify Products

2. Streamline information flow with a project management app

Pain points:

Field salesmen for building material manufacturers handle a lot of customers from various construction projects. Every project has different needs, specifications, and deadlines. These document trails are complex. If they’re done manually, they can often be inefficient and prone to human error.

Solution:

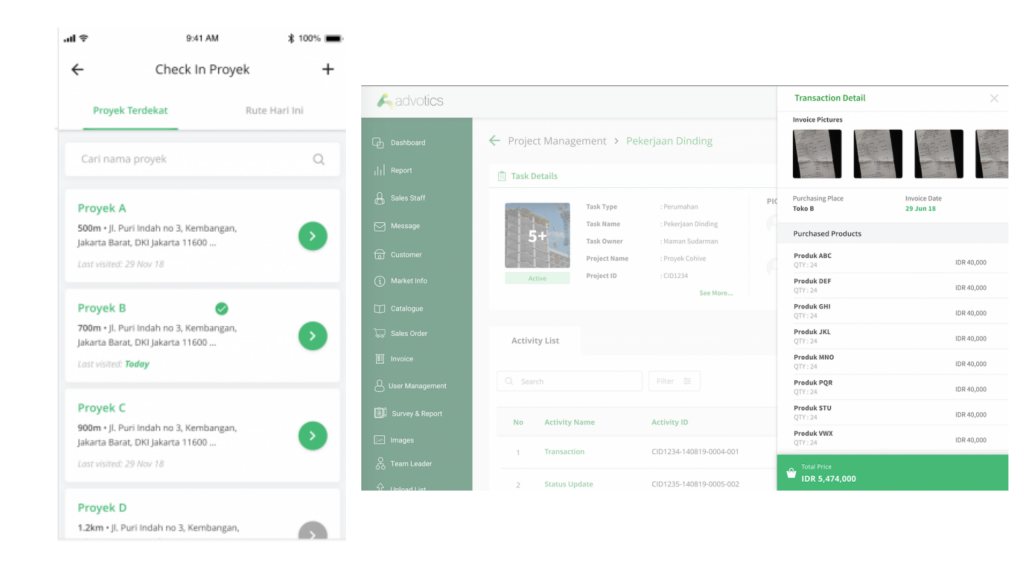

All project information (location, transaction history, PIC/contractor) is stored in the cloud so every employee with proper access can view it anytime and anywhere.

Benefits:

Principals can see all projects status so that the sales team can determine which products can be offered. In addition to that, the system can also accommodate product education for construction workers.

The absorption of building material products in the market, especially the newer products, is very dependent on the advocacy of construction contractors/workers/building owners who work on the project. A wrong installation method can affect the final quality of the product. This is why principal companies have to introduce new products to construction workers by conducting proper product training. Connected with the mobile application, now salesmen or trainers can enter their activity reports and companies can immediately check activity reports.

Read more: Project Management SaaS for Construction Companies

3. Reduce expenses by optimizing operational costs

Pain points:

High operational costs are often caused by less than optimal use of resources and delivery routes. For example, heavy vehicles such as forklifts, trucks, etc., are the biggest contributor to high operating costs. However, many companies often don’t know how long the duration of use of these vehicles is in the field. Is it maximized? Underutilized? Are there many unused vehicles in the warehouse?

Solution:

Implement each vehicle with a GPS tracker integrated with the software that will collect status, the location from time to time, and the duration of use.

The route planning system can automatically generate the most recommended route, according to selected parameters such as dynamic visiting hours, driver’s total working hours & specifications, as well as customer priority.

If the vehicle carries the product, the system can also facilitate parameters such as the type of product transported, the vehicle type, capacity and specifications, order fulfillment in the correct delivery window (date and time of delivery). All information is integrated in real-time allowing last-minute schedule changes.

Read more:

Benefits:

Each vehicle usage report will assist management in allocation and utilization. A maximized vehicle productivity can reduce operating costs, Advotics Vehicle Management System has been proven to reduce vehicle operating costs by up to 14%.

4. Market expansion strategy

Pain points:

Before penetrating a new market, a company must perform a market analysis to validate consumer demand in the area. However, most brands fail to do a market analysis because they don’t use the right technology to do it effectively. Without accurate data and numbers, companies can only see what competitors are doing in the market, not what products are being sold and what products consumers actually buy.

Solution:

Through digitized supply chain platforms such as Product Insights Analysis, companies can visualize data from each SKU and run an in-depth analysis for each product’s performance with an objective and accurate graph because the system tracks and synchronizes all data from various data sources in real-time.

Benefits:

Analyzing the best-selling products and the prices of competitors’ products can help companies find market gaps in customer needs that competitors have not yet addressed in new areas.

Read more: What is Product Insights Analysis? Importance for Principals and Distributors?