The Next Manufacturing Revolution -

Going for 4.0 With Advotics

Table of Contents

For manufacturing companies, as products become more complex, production needs to adapt to keep up with the demand. Too often, outdated supply chain operations are lacking in transparency.

Growth and expansion are key goals for most businesses: improving product quality and increasing productivity, while staying competitive and remain profitable. Representing the latest industrial revolution, industry 4.0 is a transformation in manufacturing regarding the way that machines produce and move our products.

What is the Industrial Revolution 4 0?

The first industrial revolution is the transition of people from working on a farm to a factory. It was the mechanization through water and steam power that propelled the growth of the industry and the technology development in manufacturing.

In the year of 1831, Michael Faraday discovered the electric current which soon replaced the water and steam-powered machine. The second industrial revolution is the beginning of mass production and assembly lines.

The third industrial revolution is the adoption of computers. This allows machines to automate most tasks. Then, computers started to talk to each other creating networks of computerized machines, this is where industry 4.0 is taking place today.

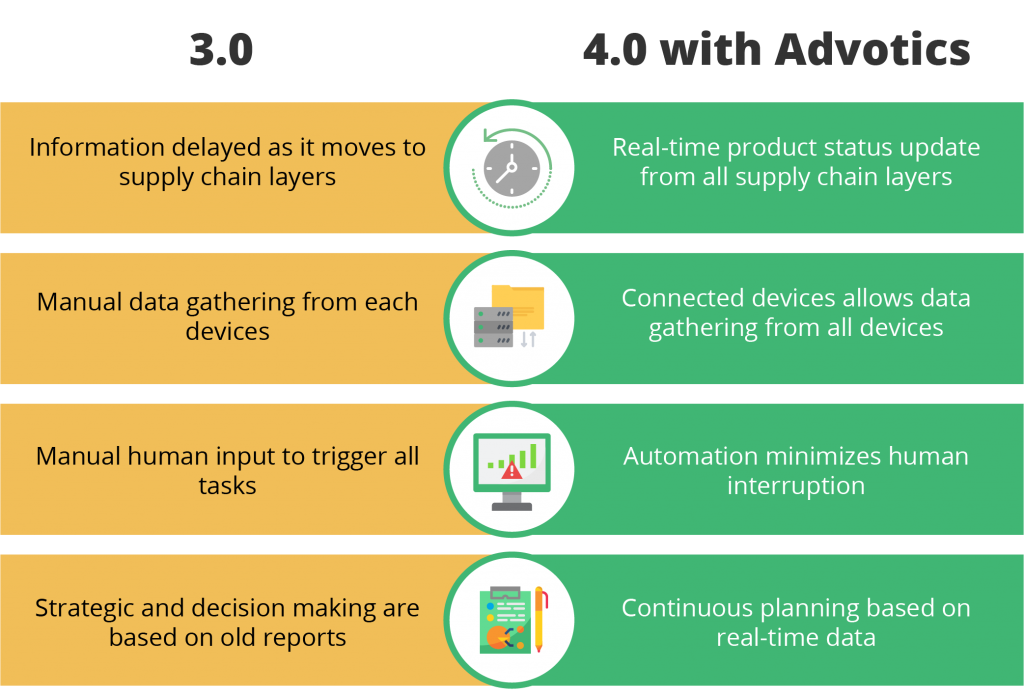

What Makes Industry 4.0 Different Than 3.0?

Machines in industry 3.0 can automate certain tasks, however, they still need human input to control and trigger actions. The idea of industry 4.0 is to have machines to make its own decisions with minimal human intervention.

For this to happen, machines, products, and devices need to be connected through the internet. This is called the IoT, or Internet of Things*. When machines began their network, it starts to gain data. Thanks to Machine Learning**, the system get smarter at identifying and analyzing data patterns over time.

Internet of Things for Manufacturers

IoT allows more devices to get connected. This enables the system to gather and analyze more the tremendous data from machines and products across logistics and supply chain layers.

A connected supply chain process can generate information to create a powerful market insight. Let’s take product sales for example. Every time an end customer buys a product, the system automatically updates its inventory level in the retailer store. From there, the distributor can know market demands from each area and the warehouse can optimize their storage flow by finding slots for new product batch even when they haven’t reached the warehouse. Lastly, the manufacturer can know the absorption rate of products so they can anticipate the production process.

Advotics platform helps companies to have a more connected ecosystem. Our system provides better visibility and insights across the entire supply chain layers, companies can improve their manufacturing and supply chain management. Integration with the Internet of Things allows the company to produce higher-quality products, faster and cheaper delivery to market while gaining an advantage over less-efficient competitors.

Advotics is an Indonesian based SaaS startup specializing in supply chain. We started in 2016 and we provide end to end integrated supply chain solution from production to distribution. So far 60+ companies have been enjoying the benefits from using our solutions, among them are Exxonmobil, Sampoerna, Danone, Mulia Group, Nutrifood, Saint Gobain, and many more.

—–

*Internet of Things= connection between physical objects and the internet

**Machine Learning= system that learn from data by identifying patterns to make decisions without human input